The intersection of superior craftsmanship and pioneering technology

The Shinshu Watch Studio is located in a Seiko Epson facility in the town of Shiojiri in Nagano Prefecture, an area blessed with beautiful views of both the Jonen and Hotaka mountain ranges as well as with fresh, crisp air and pure, clean water. The studio has the people, skills and technology to have mastery of every aspect of watchmaking from the development, design and production of movements to the manufacture, assembly and adjustment of complete watches, including cases, dials, hands and indexes. Thus the studio is one of the world’s few fully integrated “manufactures” and makes all Grand Seiko’s Spring Drive and quartz watches in-house. From the day when the studio’s predecessor, Suwa Seikosha, produced the first Grand Seiko watch in 1960, the facility has been home to dedicated engineers, watchmakers and craftsmen and women who are as committed as the members of the original Grand Seiko team to the exercise of the highest level of their skills in the making of every single Grand Seiko watch.

Spring Drive is the crown jewel of the Shinshu Watch Studio. It took nearly thirty years from the moment the idea was conceived by a young engineer in the Shiojiri facility to the creation of a Spring Drive watch that was worthy of the Grand Seiko name. The development was fraught with challenges that required advances in every aspect of the watchmaker’s art, from the creation of a new alloy for the mainspring to the use of advanced electronic engineering to create an entirely new type of regulator.

Now, over 20 years since Spring Drive was created, the 60th anniversary of Grand Seiko sees the creation of an entirely new Spring Drive movement, Caliber 9RA5, that, in size, performance and function, sets a new standard for all spring-powered watches. In comparison to Caliber 9R6 that is the mainstay of the collection, Caliber 9RA5 delivers a five day power reserve, an increase of over 60%. Its monthly precision rate has risen from ±15 seconds to ±10. The speed of the date change has been greatly increased and, despite this increased functionality, the movement depth has been reduced from 5.8mm to 5.0mm. Caliber 9RA5 takes Spring Drive technology to a new level of excellence and opens a new era in the history of Grand Seiko.

The Shinshu Watch Studio is also home to Caliber 9F, which might be the most advanced quartz movement in the world. It offers an extremely high accuracy rate of ±10 seconds per year and, through the use of a Twin Pulse Control Motor, Caliber 9F drives large and thick hands just as on every other Grand Seiko watch and just as the Grand Seiko Style demands.

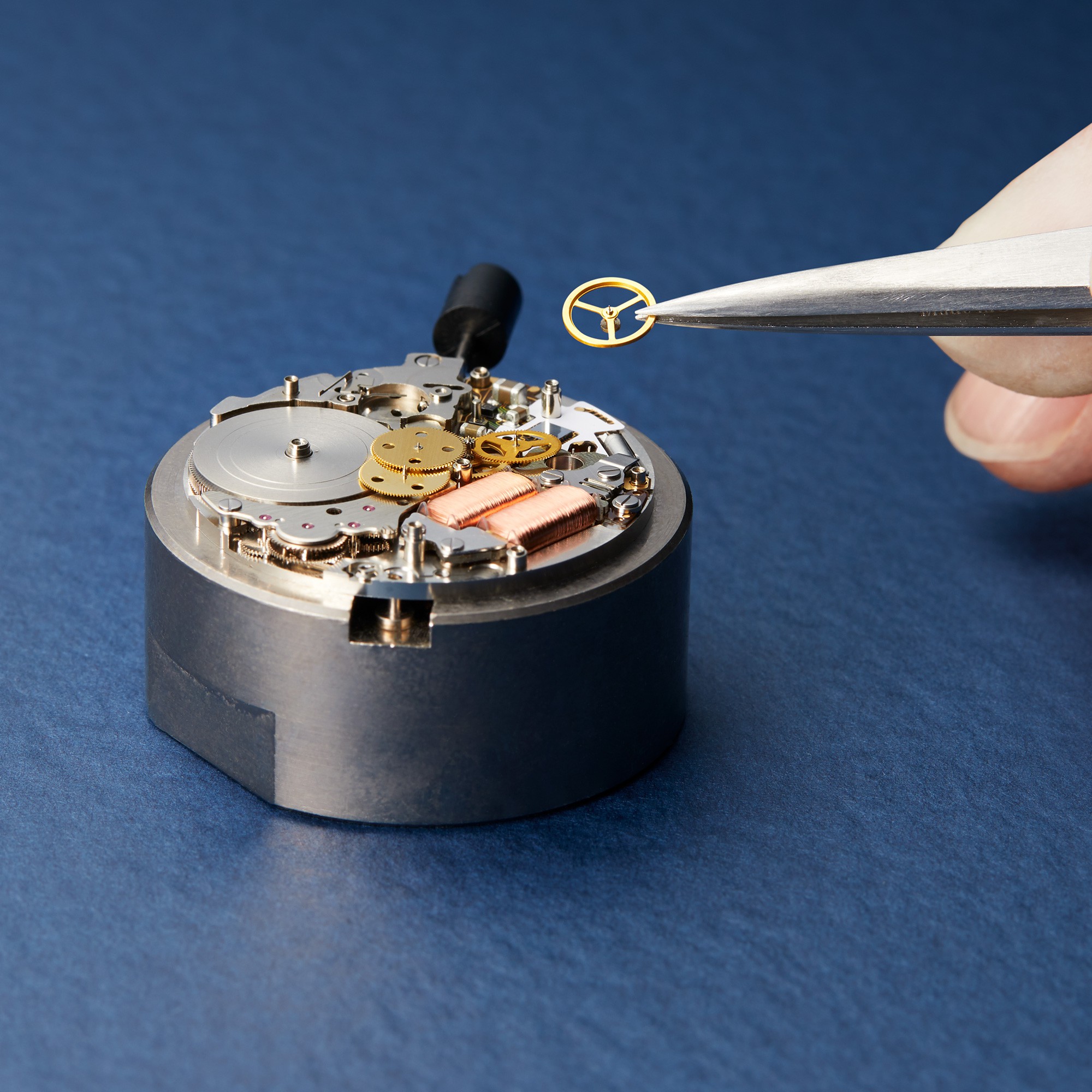

Caliber 9F is also extremely accurate, thanks to specially aged and selected quartz crystals, each of which is regulated individually. The movement also presents time extremely accurately. Unlike on every conventional quartz watch, the seconds hand driven by Caliber 9F stops exactly on the second marker, with almost no vibration of the hand. This is achieved by the addition of a regulatory wheel incorporating a hairspring to minimize any backlash in the gear train. Even the way the date changes reflects the precision of the caliber. In most watches, the date change is gradual and takes several hours to complete. In Caliber 9F a spring lever mechanism is used to change the date instantaneously in the blink of an eye. To ensure the durability of Caliber 9F, the rotor and gear train are tightly protected by a shield in a self-contained cabin. This guarantees the long-lasting quality and precision of the movement by preventing dust entering when the case back is opened for battery replacement. Hand assembled and adjusted, Caliber 9F is the ultimate quartz movement.

Beautiful watches of exquisite Japanese craftsmanship

Hand craftsmanship is the key to every step of the Grand Seiko watchmaking process. While the watch dial begins with the creation of a base plate by machine, it is the craftsmen and women of Grand Seiko who give each one its character. They plate and coat the base plates and, after the cutting and drilling processes, they assemble each part, including the indexes and hands, by hand. Even the tweezers and other instruments used by the watchmakers to place each part in just the right place are specialized tools that are customized and adjusted by the craftsmen and women to maintain their precision and to suit their particular handcraft styles. The beauty of the “snowflake” and “silken sunray pattern” dials that the studio creates are perfect embodiments of the craftsmen’s and women’s skills and they have a particular Japanese heritage and aesthetic. Created in 2005, the “snowflake” dial was inspired by the dial finish of a watch known as 56GS that had been manufactured by Suwa Seikosha in 1971 in order to reflect the rough surface of the snow that lies in the Shiojiri area for several months a year. The “silken sunray pattern” dial has a silken shimmer and utilizes an intricate array of fine lines to capture and reflect light in a radiating fashion that creates a deep brilliance unlike anything else. This dial, too, shows the expertise of the studio’s craftsmen and women at its finest. First, a silver coating is applied to the base plate, after which it is brushed it in a special solution. Then, a thick, clear coating is applied and polished to form a smooth surface onto which the array of lines is drawn. At every stage, each dial is treated by hand and each is inspected individually to ensure its perfection.

The studio is also expert in Zaratsu polishing. As the case is pressed against the rotating disc, the craftsmen and women entrusted with this task can use only their eyes and the feeling in their fingertips to sense the exact angle and pressure required. Through their fingertips, they can feel the heat generated, the vibrations and the rate at which abrasive is being used up and make whatever adjustments are needed. This sensitivity is the result of years of experience, and even then, there are only a few individuals in the world that possess enough talent and skill. Most of the Zaratsu polishing the studio does is on stainless steel and titanium but, in addition, they work on the difficult-to-process 18k gold and platinum cases used in the Masterpiece Collection. Within the Shinshu Watch Studio, there is also a space dedicated to jewelry watches. Here, the craftsmen and women set diamonds and other precious stones and work on precious metal cases to create exquisite timepieces that embody their profound skill, experience and dexterity.